This artical tell you how to retip/weld diamond segments on core barrel.

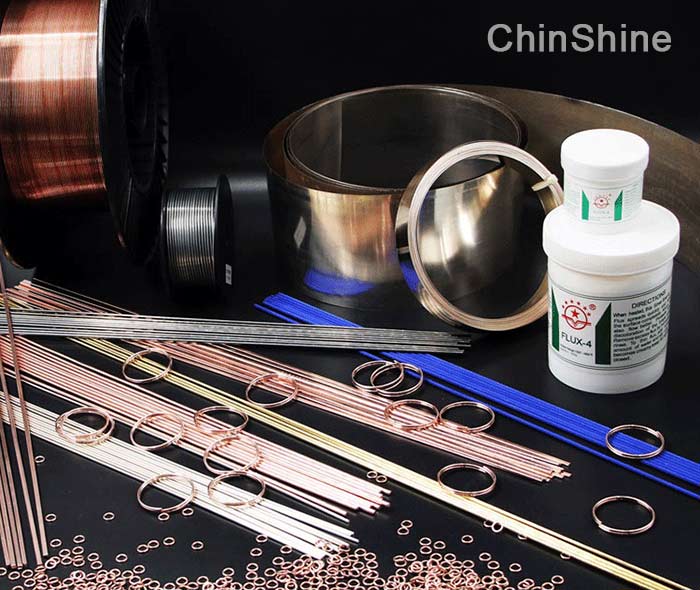

Worn out diamond core drill bit segment or damaged core drill bit do not always need throw away. Although ChinShine can't provide a re-tipping service at your side, we make diamond core drill bits, diamond segments and provide the silver solder, magnet holder, flux, and welding machine, so you can do the welding yourself. We can make various diamond segments for fast, free drilling in concrete and stone, all kinds of bond and formula for your choice, such as arix diamond segments, dimple diamond segments, roof diamond segments, turbo segment..... The high quality polycrystalline diamonds ensure excellent drill speeds and footage.

Before re-tipping, check the following:

• Check the core bit thread to see if it is damaged

• Check the barrel body to see if it is too thin or bend

• Check the outside diameter of the barrel for roundness or damage

If all these are serviceable, retipping is possible. Your core body can be brazed by your local saw doctor or sharpening outlet, or any engineering workshop that offers brazing services.

If you want to re-tip diamond segments on core barrel by yourself, you will need these tools:

Heat source, gas or high frequency welding machine

Silver welding Solder

Flux

Silver Solder: Use the right brazing rod or silver solder. You need silver solder rods, cadmium free, with 40% to 45% silver.

One silver welding stick will usually do 10-20 segments, depending on your skill.

Flux: A fluxing agent is required for all brazing jobs. The flux removes oxides from the base material and prevents oxidation during the heating process, thus enablng the free flow of the solder, you can find the cheap flux at your local market.

Diamond Segments: Obviously, we make all kinds of premium quality diamond segments for your choice, such as arix , roof, turbo, dimple... .

Here are the diamond segments quantity per core bit:

When replacing segments, just count how many you need.

For crown segments, we just need an accurate diameter of the crown.

You will then need to pick the style of segment you want:

1. Remove remaining diamond segments if replacing all segments (use heat and pliers to melt the solder), otherwise check existing segments if replacing lost segments only.

2. Carefully clean the barrel welding surface with an angle grinder.

3. Gently clean the bottom and end surfaces of the segments a little with a 100/120 grit grinding wheel. Try not to expose any diamonds as this will reduce the strength of the brazing, possibly with the risk of segment loss.

4. Add flux to the brazing surfaces of the diamond segments and the barrel and let dry.

5. Check the thickness of the segments and put your brazing magnet tools on the inside of the core. Choose the magnet setting so that the segment clearance on the outside will be about twice the clearance on the inside. This normally means using a 0.5mm magnet clearance when the difference is up to 1.5mm between segment and core thickness, and 0.75 mm on all other dimensions.

6. However, when coring very abrasive materials (like natural limestone or asphalt) increase the clearance one step on the inside, but never more than to 50/50 clearance.

Note, on very thin segments it may be impossible to get double the clearances on the outside, but never make the inside clearance larger than that of the outside clearance.

Start brazing by gently warming up the core under the segment and continue working with the flame sideways and up and down over the whole segment. Never keep the flame still and never use too hot a flame. Make sure the whole segment is warmed up and gets the same light red colour all over.

Add silver solder and continue warming until the solder melts and spreads. The silver solder should be melted by the heat of the metal pieces being joined, not by direct contact with the flame of the torch.

Continue to the next segment and repeat the brazing until all segments are brazed. Check each brazing carefully. If any brazing does not look good, braze again!

scan to wechat: